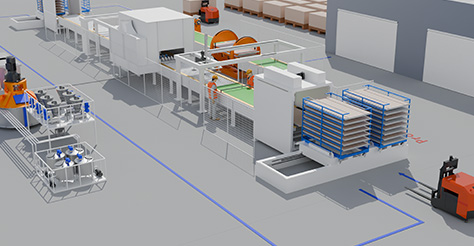

Designing a fully automated production line for creating flexible stones would involve a combination of various processes and machinery to efficiently manufacture these products at scale. Here is a conceptual outline of the components that could be part of a full auto flexible stone production line:

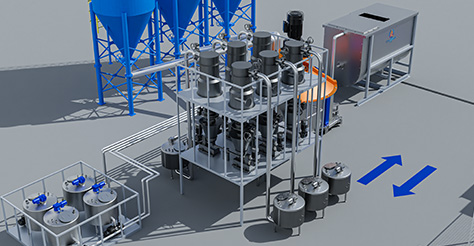

This station would involve preparing the raw materials required for creating flexible stones, such as silicone rubber or flexible polymer material. Automated systems could be used for measuring and mixing the materials in the correct proportions.

An automated system for mixing pigments or dyes with the base material to achieve the desired color for the flexible stones.

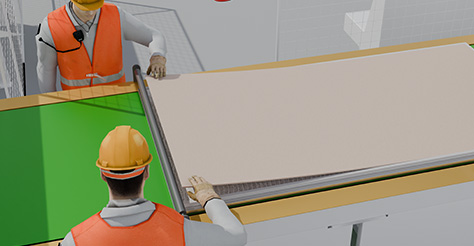

Automated molding machines that can pour the mixed material into stone-like texture molds. These machines should be equipped with sensors to ensure accurate filling and consistent results.

After molding, the flexible stones would need to go through a curing process. A chamber with controlled temperature and humidity levels could facilitate the curing process efficiently.

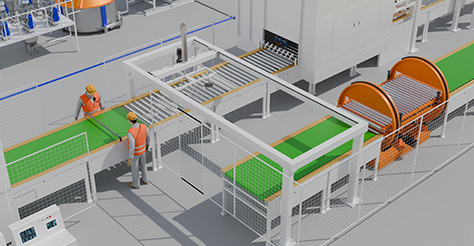

Automated systems for demolding the flexible stones from the molds and inspecting them for quality control purposes. Any defective products could be sorted out automatically.

Automated tools for trimming excess material and refining the shape and texture of the flexible stones to meet quality standards.

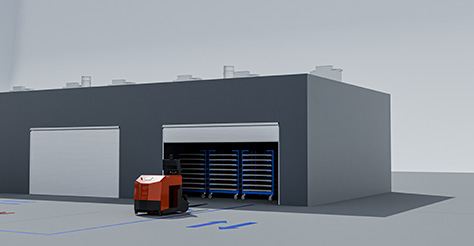

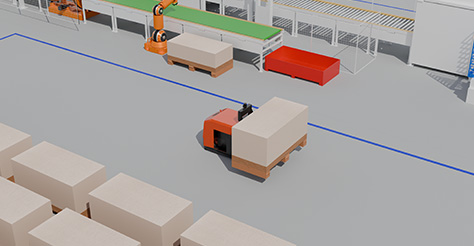

Once the flexible stones are ready, an automated packaging system could sort and pack them into containers or boxes. Labels with product information and branding could also be applied automatically.

Incorporate sensors and cameras at various stages of the production line to monitor the quality of the flexible stones and ensure that they meet the required standards.

Implement a system for monitoring the performance of the production line, scheduling maintenance tasks, and detecting any issues to ensure smooth operations.

Centralized control system that oversees the entire production line, coordinating the activities of different stations and ensuring seamless operation.

Building a fully automated flexible stone production line would require expertise in industrial automation, material science, and product design. Custom machinery and equipment tailored to the specific requirements of creating flexible stones would need to be developed and integrated into the production line. Additionally, safety measures and protocols should be implemented to ensure a secure working environment for the operators and maintain the efficiency of the production process.

Designing a drying room for flexible stone production involves creating an environment where the stones can cure or dry effectively after they have been molded. Here are some key considerations and components that you might incorporate into the design of a drying room for flexible stone production