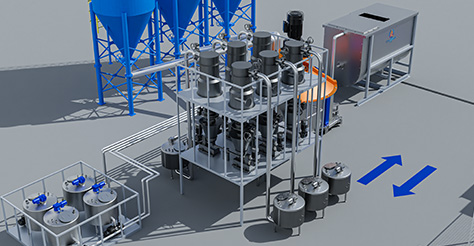

Install systems to control and maintain the temperature and humidity levels within the drying room. This is crucial for the proper curing of the flexible stones.

Ensure proper ventilation to promote air circulation within the drying room. This helps in maintaining a consistent environment and expelling any fumes or odors from the curing process.

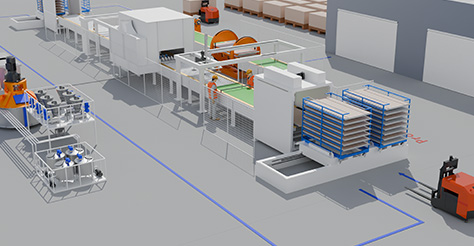

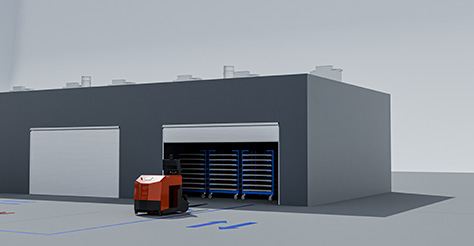

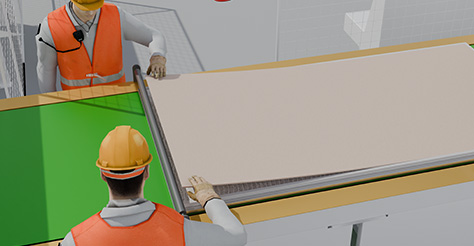

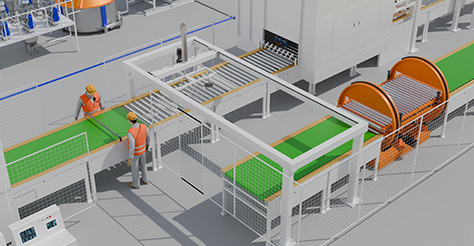

Provide racks or shelves within the drying room where the flexible stones can be placed for curing. These should be sturdy and designed to hold the stones securely.

Install adequate lighting to ensure visibility within the drying room. Uniform lighting helps in inspecting the stones and monitoring the curing process.

Implement timers and monitoring systems to track the curing time of the flexible stones. This helps in ensuring that the stones are left to dry for the correct duration.

Incorporate safety features such as fire alarms, emergency exits, and fire extinguishers to ensure a safe working environment.

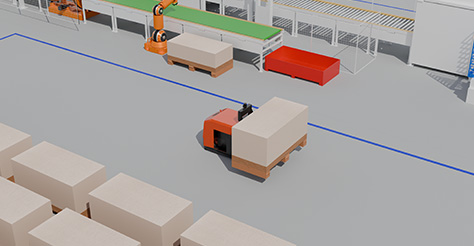

Design the layout of the drying room to optimize space utilization and workflow efficiency. Consider factors like aisle space for movement and accessibility to the racks or shelves.

Set up designated areas within the drying room for quality control inspections. This allows for immediate assessment of the flexible stones during the curing process.

Depending on the materials used and the curing process, consider incorporating dehumidifiers or moisture removal equipment to accelerate the drying of the flexible stones.

Establish regular maintenance schedules for cleaning and upkeep of the drying room equipment to ensure optimal performance and cleanliness.

By incorporating these components into the design of a drying room for flexible stone production, you can create an environment that facilitates the proper curing and drying of the stones. Ensuring consistency in temperature, humidity, and airflow will contribute to the quality and durability of the flexible stones produced.