In the ever - evolving landscape of architectural and decorative materials, the PU Cultural Stone Mold has emerged as a revolutionary product, bringing about a new era of innovation and functionality.

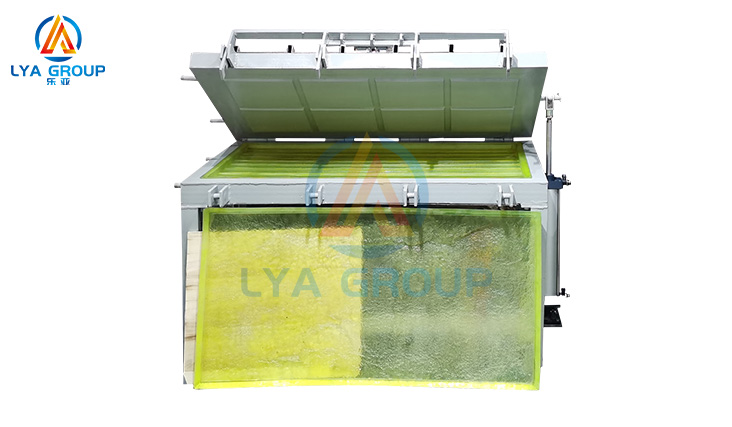

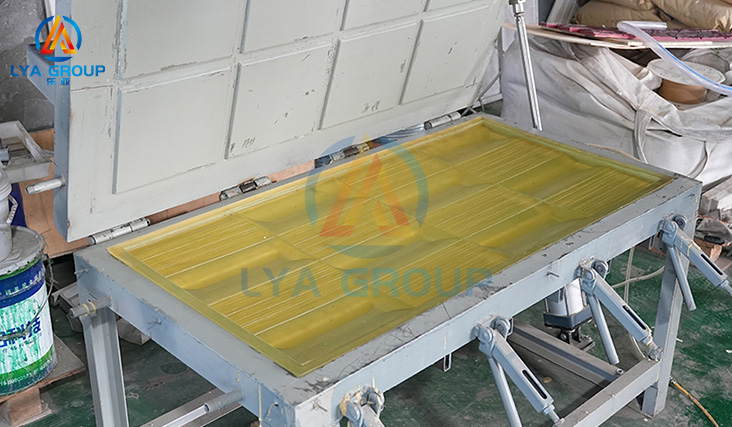

PU, short for Polyurethane, serves as the core material for these molds. Renowned for its outstanding flexibility and durability, polyurethane enables the creation of molds that can precisely replicate the most intricate details of natural stones. The manufacturing process begins with the creation of a master model. This can be achieved through high - precision 3D scanning of natural stones or meticulous hand - carving techniques. Once the master model is ready, liquid polyurethane is carefully poured into it. After a curing process under specific temperature and time conditions, the polyurethane solidifies into a mold, which is then subjected to finishing touches and quality inspections to ensure its accuracy and surface quality.

PU Cultural Stone Molds are designed to withstand the test of time and heavy usage. They exhibit high resistance to wear and tear, making them suitable for long - term production runs. This durability not only reduces the frequency of mold replacements but also ensures consistent product quality over an extended period.

In terms of cost, PU molds offer significant advantages. The relatively low - cost raw materials and straightforward manufacturing process contribute to a lower overall production cost. Additionally, their long - lasting nature means fewer replacement costs, providing a high - value solution for manufacturers in the long run.

The flexibility of polyurethane allows the molds to capture every nuance of natural stone textures, from the fine veining of marble to the rough, rustic look of granite. This precision ensures that the artificial cultural stones produced are virtually indistinguishable from their natural counterparts, meeting the high - end aesthetic demands of modern consumers.

PU molds are lightweight, which simplifies the manufacturing process. They are easier to transport, store, and operate, reducing labor intensity and enhancing production efficiency.

In homes, hotels, and restaurants, artificial cultural stones made from PU molds are widely used to create stunning feature walls. They can transform a plain interior space into a warm, inviting, and stylish environment. For example, a living room with a PU - made cultural stone accent wall can exude a cozy, natural charm, while a hotel lobby adorned with such stones can create a luxurious and unique atmosphere.

These molds play a crucial role in enhancing the visual appeal of buildings. Whether it's a charming villa, a commercial complex, or a historical - style structure, the use of artificial cultural stones produced from PU molds can add a touch of elegance and character. The stones are also weather - resistant, making them suitable for various outdoor environments.

In parks, gardens, and other outdoor spaces, PU - made cultural stones are used to create beautiful rockeries, garden paths, and decorative fences. They blend seamlessly with the natural surroundings, offering a cost - effective and long - lasting alternative to natural stones.

In conclusion, the PU Cultural Stone Mold, with its advanced material properties, remarkable advantages, and wide - ranging applications, has become an indispensable tool in the architectural and decorative materials industry. It not only provides a practical solution for manufacturers but also enriches the design options for architects, interior designers, and landscape artists, contributing to the creation of more beautiful and sustainable built environments.